COMPANY

For more than 20 years, we have been dedicated to the design, fabrication

and erection of steel works,

able to meet any kind of demand, shape and size.

We put the utmost attention into every detail, ensuring maniacal control over every stage of the production process.

Our company follows the entire production process: all work is designed, manufactured and assembled in-house.

Our strengths

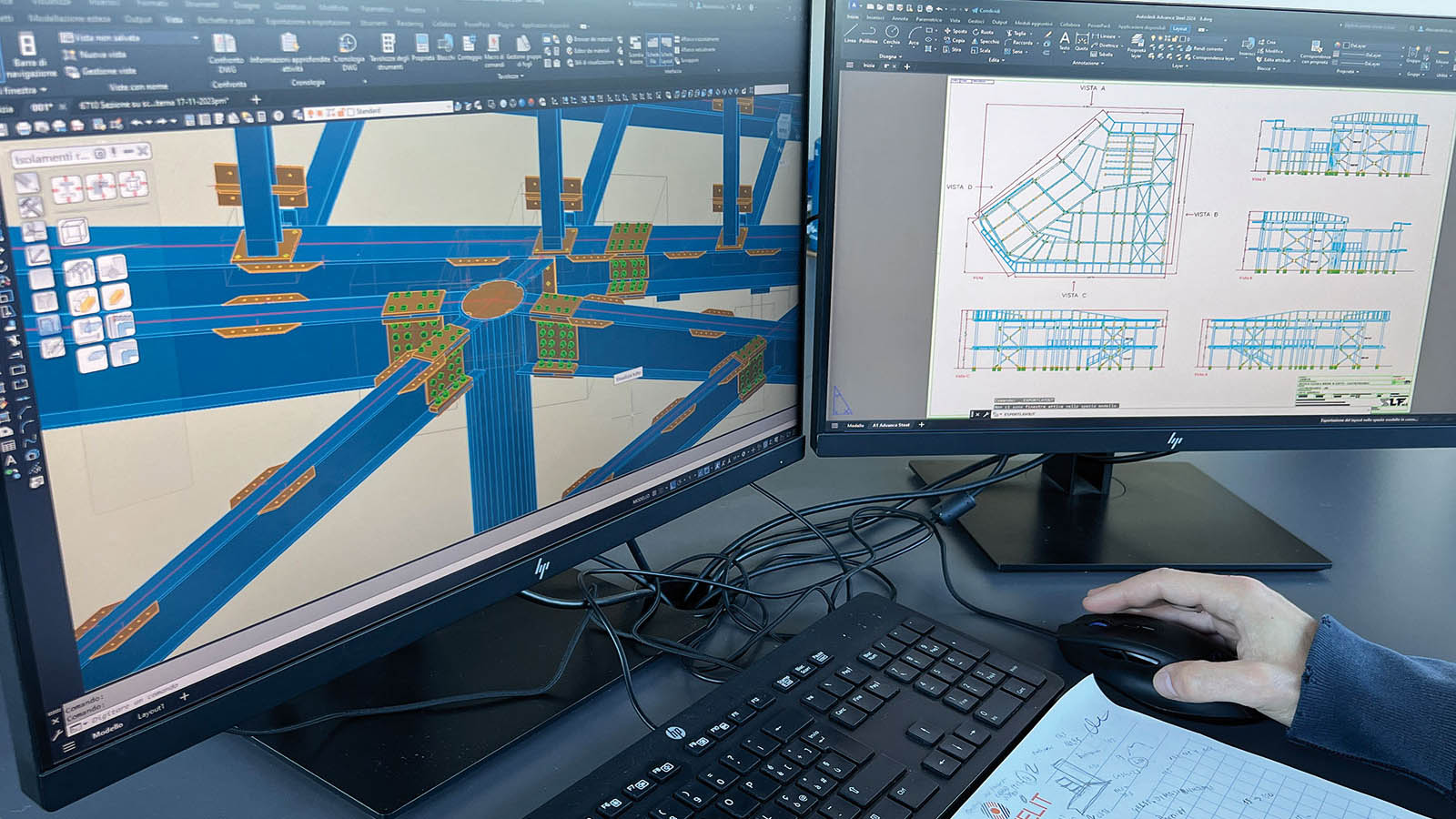

Design

Our in-house design service represents our greatest pride. Using sophisticated 2D and 3D modeling software, we are able to provide our clients with a highly efficient rendering service. This phase is of great importance as it allows us to transform an idea into a concrete design and provide the client with a sharp and defined image of the product.

Quality

Our staff is properly trained and certified. For every stage of production. From specific certifications for welding processes to certificates for the use of various lifting equipment. From certificates for the use of aerial platforms to first aid, work at height and occupational safety training courses.

Assembly

Meeting deadlines also depends on the speed of erection on site. Careful planning makes it possible to foresee critical issues, select appropriate materials, and precisely define the time and stages of erection, ensuring efficient and rapid execution of the work. Our highly qualified installation personnel and a large fleet of vehicles and tools enable us to deal with every situation and need safely and promptly, always guaranteeing the highest quality. Therefore, all of these factors are essential to achieving our goals.

Complex projects

Flexibility as the key to success. Our company understands the importance of flexibility when it comes to meeting the demands of clients seeking unique, complex projects with challenging architectural designs and unconventional materials. Our team of experienced professionals has a deep understanding of the project as a whole and detailed knowledge of the materials involved, enabling them to assess the technical feasibility of the client’s requests and provide alternative solutions, if necessary.

CERTIFICATIONS

The added value for market differentiation

Our company is certified ISO 3834 for welding processes, ISO 1090 for CE marking in EXC3 class and SOA OS18 in 2° class for public procurement.

In today’s highly competitive market, certification of our system is an essential requirement and a means of differentiation from unqualified competitors.

STAFF

Human Capital: Training for Business Success

Our staff has developed extensive experience in every branch of this sector, both in terms of workshop production and on-site assembly. Each worker has been adequately trained for any eventuality. They are equipped with welder certifications, have undergone all the necessary safety training courses, and hold certifications for forklift driving and aerial platforms.

STRUCTURE

Our production area

L.F. Srl has at its disposal a spacious production area of 1300 square meters and a surrounding yard of 2300 square meters, allowing us to work with precision and quality in any circumstance, whether for the production of small structures or for the realization of large projects such as bridges and industrial buildings. This space enables our company to also carry out pre-assemblies of any type of installation, ensuring that even the most complex structures from a production standpoint reach the customer without any errors. Additionally, our company is constantly committed to investing in new technologies and cutting-edge machinery to improve the productivity and quality of our products.